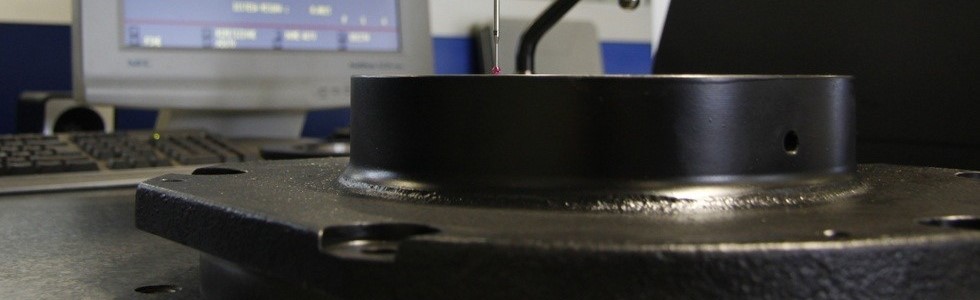

Thanks to mechanical engineering passion and precious know-how built up over the years, but also to the avant-guard fleet of equipment and the process optimization, Tecnodelta is a key supplier for parts with heavy production cycle, which need different machining and treatments.

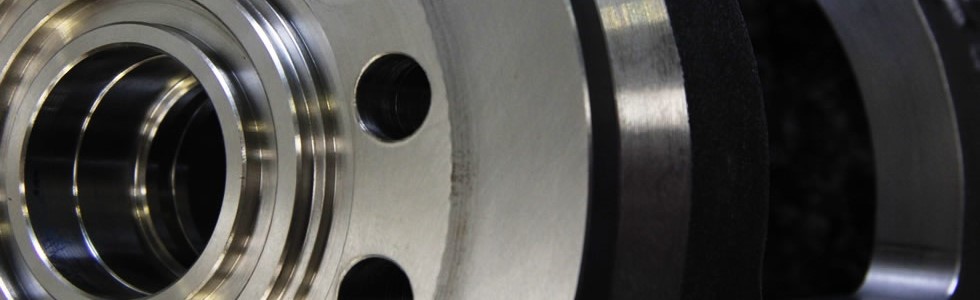

In the plant of Berbenno di Valtellina of 2.800 meters square, the company can count on a focused CNC machinery fleet that allows to process up to 750 mm diameters on turning and 1600x760x700 on milling and finishing.

The secret hidden behind our precise mechanical processing is certainly our capacity to keep constant production technology updated in order to identify the most efficient and the best quality/price solutions.

Daily processing takes place on ferrous metals:

- cast irons

- structural carbon steels

- hardened and tempered steels

- stainless steels

- 17,4 PH

- F55, F53

- inconel, duplex, super duplex

and on non ferrous metals

- aluminum and its alloys

- bronze

- plastic materials.